Hive Aggregates

Hive Aggregates will use industrial by-products and waste to create sustainable building products.

The global building products industry is resource and carbon-intensive. It is estimated that if the cement industry alone were a country, it would be the third-largest carbon emitter in the world – behind only China and the US.

We think that the use of sustainable products has the potential to significantly reduce the current carbon-intensive practices.

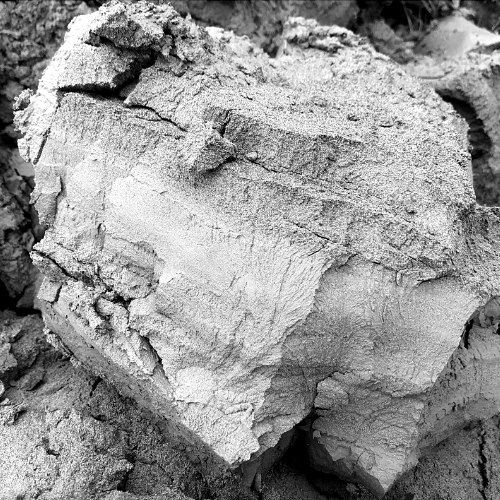

Part of our solution is to turn pulverised fuel ash waste into a sustainable cement substitute. The ash originates from the burning of coal in power stations. The team will use an innovative bulk drying technology to convert the ash into a cement substitute. The plan to convert the ash has numerous benefits, including recycling waste products, reducing the use of natural resources, and saving a significant amount of carbon.

The benefits of pulverised fuel ash and our projects

A key benefit of the sustainable material is that it acts as a replacement for traditional cement in concrete mixes. This is due to its natural pozzolanic qualities.

Studies estimate that each tonne of pulverised fuel ash used in cementitious applications can save the equivalent CO2. Hive Aggregates has used its land development expertise to secure deposits of pulverised fuel ash in the UK. Our first project aims to recycle up to 7 million tonnes of ash waste from a site in Nottinghamshire. The project will produce up to 500,000 tonnes of cement substitute material per year.

Once the first project is underway, there is the potential to save many millions of tonnes of carbon. We aim to follow with other projects of a similar scale.

Hugh Brennan

UK Managing Director

Jake Barnes-Gott

Hive Aggregates Project Director

Hive Aggregates has launches its first project – The Retford Circular Economy Project.

The Retford Circular Economy Project, located close to Retford, Nottinghamshire – UK. The project aims to carefully extract pulverised fuel ash (PFA) waste from a former landfill and process it using innovative technology to produce a sustainable cement alternative.

The project will extract around 300,000 tonnes of pulverised fuel ash (PFA) waste per year from a landfill site, turning it into a sustainable cement replacement and providing a vital tool to decarbonise the building products industry at a time when ‘fresh’ supply of PFA from existing power stations is ending.